Xiangdafeng Technology (Beijing) Co., Ltd Copyright No.2020041289-1

Address:712, 7th floor, building 154, brick factory Beili, Tongzhou District, Beijing

Mobile:+86 18901353186 Tel:010-82900580

Fax:010-82900580Mail:market@xdfpcba.com

At present, the quotation of PCB production is given by PCB manufacturers. With the continuous progress of Internet technology, many PCB manufacturers now have online pricing of PCB. However, the main determinants of PCB quotation are as follows:

1. PCB area (size)

Area refers toThe size of PCB design drawings. If it's a rectangle, it's length x width. If it is a circle, or other irregular graphics, it is calculated according to the maximum profile range. Generally, the waste of materials caused by irregular shape should be reduced.

2. PCB batch size

The larger the batch,The lower the price spread to each board.

3.PCB板材料

Sheet metal isPCB manufacturer is the most core material, the board factory generally default to use the long-term cooperation supplier's board. But for PCB with special requirements, the designer should specify the material, and the price will be different. For example, there is a kind of Rogers sheet used for microwave RF, and its price is 10 times that of ordinary sheet. The commonly used sheet materials in general plate factories are Shengyi, Hongren, Jiantao, etc.

4. Number of PCB layers

Single panel, double sided board, 4-layer plate, 6-layer plate, even number of general plates. The higher the number of plates, the higher the price, the multiple growth.

5. Delivery date

NormallyThe production cycle of single and double-sided boards is 3-4 days. If it is particularly urgent, you can choose 48 hours or even 24 hours, but the cost will increase. If there are problems in the design that need to be clarified, the time should be counted from the time when all the problems are confirmed.

6. Whether special process is needed

Each factory will have its own process parameters . If your design exceeds the process capacity of the plate factory, they have to carry out special control during production, and the production cost will increase. In addition, the following conditions will also affect the quotation.

(1) Plate thickness. The conventional thickness of double-sided plate is 0.4, 0.6, 0.8, 1.0, 1.2, 1, 6, 2.0, 2.4 (mm). If you want to produce plates of other thicknesses, the price will go up.

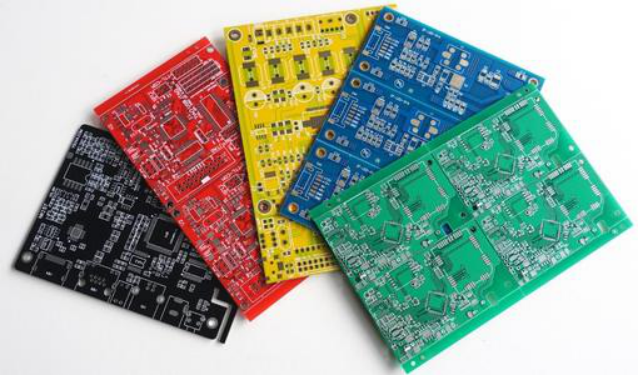

(2) Color of solder resist ink. Printed circuit boards are generally covered with a layer of ink, this layer of ink does not touch solder, called solder mask. Green is the most common and economical, so solder mask is also called green oil layer. Other colors are red, yellow, blue, white and black, as shown in figure 3-135. Among them, black ink board is the most difficult to produce, and the cost will be high.

chart3-135

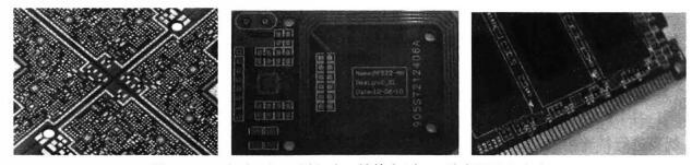

(3) Pad handling. Copper is easy to oxidize in the air and affect the welding, so the parts that need to be welded should be coated, which is also called surface treatment in some factories. Its processes include lead tin spraying, lead-free tin spraying, gold precipitation, nickel gold plating, OSP, silver precipitation and so on. Figure 3-136 shows the three most commonly used surface treatment methods.

Tin spray is the most common process in PCB industry, which has the advantages of good weldability and low cost. The disadvantage is that the flatness is not good, especially when large area windows are opened, it is easy to appear uneven. Lead free tin spraying is to meet the requirements of environmental protection, which is a little expensive.

Gold deposition is the use of replacement reaction to form a thin layer of gold , which has good flatness and weldability.

Nickel and gold are first plated on the weld,Re gilded, it is characterized by wear resistance, used for frequent plugging positions, such as gold finger and key positions.

OSP is an organic protective film formed by chemical reaction between liquid medicine and copper skin. This film has anti-oxidation, heat shock resistance and moisture resistance. OSP is generally used less.

Silver sink finger is coated with silver at welding position,This process is less used. Silver is easy to be oxidized and blackened in air, so it is required to be welded within the specified time.

chart3-136 three kinds of surface treatment methods: gold precipitation (left), tin spraying (middle) and nickel plating (right)

(4) Electronic test. Electronic test is used to detect whether each solder joint of the same network has an open circuit in the circuit, and whether each solder joint of different networks has a short circuit. Both proofing and small batch boards are tested with flying needles. We can think of flying needles as two probes of a multimeter. They can move quickly and locate accurately. They can complete the measurement of two points in a very short time, and compare the on-off status with the existing data. If the place that should be disconnected is connected, or the place that should be connected is disconnected, record it. A large number of boards are generally tested by a needle bed. It needs to make a test fixture, which is a parallel measurement method, with fast testing speed and high cost.

(5) The number of panels. In order to save the cost, two or more boards can be put together in one design drawing and sent to the board factory. This method can save the engineering cost and film cost of the board factory, but some board factories need to increase the cost.

(6) Character color. The color of the words on the PCB is white. If you want to make other colors, the cost will increase.

The more economical method of double-sided plate is no special requirements for plate material , plate thickness of 1.6mm, green, tin spray, white, 100% electronic test. Board size, batch, delivery date and number of panels should be determined according to the specific situation.

Three key processes in HDI PCB......

Why plug holes should be made ......

Analysis of the main causes of......

PCB design company analyzes th......

PCB via design specification...

The type selection of componen......

Common PCB high frequency and ......

Factors affecting PCB cost...

SMT customer incoming material......

Definition and classification ......

Consultation hotline

010-82900580